Windmills of Scoraig

An informal tour, by Hugh Piggott year 2000

This tour is always out of date :-)

things change too fast

CountZ.com

since 7th October

2000

Back to Hugh's

homepage

This is an very brief guide to the windmills which provide electricity

to households on a small peninsula with no road access or power lines (called

Scoraig). I hope I don't step on too many toes by telling it like

it is and describing our experiences of various commercial makes, old and

new.

Links to machines below:- Ampair, AIR,

LMW,

Proven,

Survivor,

winco,

chinese

My own designs, including also the

African

AWP3.6

and the ITDG alternator

Here is some text to read, while you wait for the pictures to load

Intro Hugh Piggott

Windpower fanatic. Born Scotland 1952, educated

Edinburgh and Cambridge. After graduation, went back to the land

in NW Scotland where I remain. For 4-5 years I did without electricity

except what I could rob off 12V vehicle systems on rare shopping expeditions,

by connecting an elderly car battery to bits of loose wire. This

ran my cassette tape machine.

In 1978 I got seriously bitten by windpower and have been

partly or totally obsessed with it ever since. This is a windy place

and very dark in winter, so there is a strong sense of victory when you

can harvest energy from a crashing gale and swamp the house in dazzling

light. Lots of bits would drop off my windmill(s) but I persevered

and ended up making windmills for most of my neighbours. They still

ring me up when they need the windmill fixed. There are about 30

windpower systems within a few minutes' walk of my house.

In the late 1980s I decided to broaden my perspective

and I started working on windmills built by others. I was amazed

to find that bits drop off them too (I thought it was just me). In

fact it turned out that I was pretty good at fixing windmills by then and

so I did some work with manufacturers, testing and developing machines,

in the demanding conditions we have here. I also wrote up some of

my ideas and helped teaching courses at the Centre

for Alternative Technology in Wales. Stopped milking a

cow and bought a fax machine.

More recently I have designed a windmill for manufacture

in Africa

and also installed some direct AC hydro systems. I find hydro

very exciting because it provides much more energy at lower cost (on a

good site) and you do not need batteries. I hate batteries.

In 1999 and 2000 I have worked as consultant to a TV company,

designing and installing a wind/hydro system for castaways

on an island.. I have also been doing another developing world project

for ITDG, culminating in a permanent

magnet alternator design you can download for free.

Ancient History

When I moved here in 1974, most people used oil lamps for lighting,

because this was simpler than running a diesel generator. There is

not a lot of money around on Scoraig, but the atmosphere is generally quite

relaxed. Planning and discussion are favorite occupations.

The working day is often curtailed by bad weather, so there is no point

in being in a hurry.

One neighbour had an old battery charging 'Freelite' made by Lucas.

I would take my tape machine 12 volt battery along to him for charging,

but I also messed around trying to build a windmill myself. The first

attempt was a bicycle-hub dynamo which I sat on the rooftop. It worked,

but it was really noisy in the house. In those days I was a 'back

to the land' hippie type, and my resources were pretty thin.

.

. .

.

I struggled for a long time to build something workable, but that's

another story. We had a lot of fun finding out what worked and what

didn't. This single bladed machine for example (built by my cousin,

Topher

Dawson) worked after a fashion but the pitch control system never quite

got perfected.

I had a lot of help from friends like Alan

Bush, Alan Beavitt, and countless others, and I read some books.

Around 1980, I made quite a number of 2-bladed windmills based on 24volt

dynamos from Austin Champ Jeeps. Many of them are still in use today,

although they have been repaired and modified a few times over the 20 years..

Output is around 300 watts from a 6 foot diameter rotor.

and as the trees have grown, I have had to increase the heights of

them.

Here is an old Winco being moved to

a new site by a tractor, complete with its tower. Sadly this machine

is no longer working today. The linkages wore out and the commutator

gave constant problems.

Year 2k

During the 1990s a number of windmills were imported to Scoraig,

and I learned a lot more about the art of wind turbine mechanics. Much

of what I have done has been repair work, because I was using secondhand

parts, or fixing up something which fell apart unexpectedly. I developed

some designs of my own at the same time, and

published

some stuff about how to build small wind turbines.

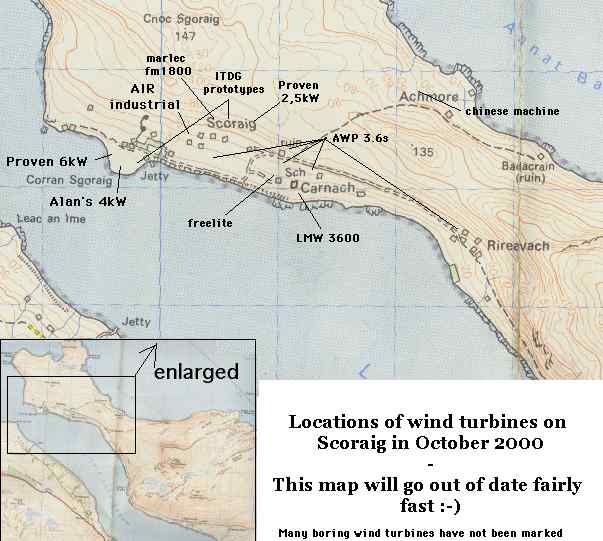

What follows is a guide to the ones which are around in year 2000 (I

am struggling to update it in places too), and what stuff has happened

getting to here. Awful things do happen to small wind turbines,

as you will see, but remember - these machines are working, and bringing

joy and light to their owners. Being a mechanic I mainly see the

breakdowns.

Links to machines below:- Ampair, AIR,

LMW,

Proven,

Survivor,

winco,

chinese

My own designs, including also the

African

AWP3.6

and the ITDG alternator

Here is the LMW3600 which was installed

here, to heat the Primary school, in 1990.

the

view is southeast, up the loch.

the

view is southeast, up the loch.

This machine taught me that I was not the only person who had problems

producing a good design of windmill. We had a lot of problems with

the LMW during the first few years.

It makes a very loud humming noise which swells and reverberates.

The tail furling system didn't work properly, and it ran too fast,

which wore out the blade edges.

This in turn caused vibration, fatigue and failure of vital parts such

as the tail, and the alternator mounts.

In other words it fell apart, repeatedly.

I have modified the tail so that it furls at about 2kW and it has now

gone for several years without problems. We have gradually grown

used to the noise and we don't notice it these days.

some blade erosion in this picture.

some blade erosion in this picture.

Ultimately, this has been a successful installation, and it keeps the

school supplied with ample electricity, although it never could have provided

sufficient heat. The average output is under 1kW - not enough to

heat a building of that size. But the rotor diameter is large (5m.

16') and so it catches plenty of power in low winds, to keep the school

supplied with light, and power for computers, vacuum cleaner, photocopier,

etc.. And in windy weather it does produce enough surplus to heat

one room to a very nice temperature.

Not many small windmills are built to give good service in very windy

conditions.

They work OK on other sites, where there is less wind, but in an exposed

coastal location like ours the problems show up early.

Some of my neighbours have owned AIR

machines from Southwest Windpower (Arizona), but their life expectancy

has been about 2 weeks. Commonest failures are burned out electronics

and broken blades.

After-sales service has been absolutely brilliant. Spare parts

and replacement machines have been supplied promptly and without quibbles.

On one site the machine was upgraded to an 'industrial' (very expensive)

version free of charge, and this has lasted almost for a whole year on

one occasion.

Here is a picture of the site.

The owners live in the little house on the right. We had to fix

a piece of sheet metal to the tail after the yaw bearing started to seize

up. It's quite a powerful machine for its size, given a good wind.

But we all know about it when it is running - it's almost as noisy as the

LMW in normal conditions, and when it hits full power it's louder than

a chainsaw.

The other family who had an AIR machine were lucky enough to be given

an old Marlec FM1800 as a replacement. This is a sturdy machine,even

though the electrics are horribly complicated.

We have now moved this machine up the hill to get away from the trees.

We tried Marlec Rutland72 watt machines for a few years, but

the stators would normally fail after about one year, and you can only

replace the stator a few times before the bearings work loose, and then

you need a new alternator. Marlec gave up making spare stators for

their older models, and I began to lose interest in Marlec.

Especially since they 'upgraded' the fm1800 by giving it only 2 blades.

One machine which gets full marks is the Ampair

Hawk

.

.

It only produces 100 watts but at least it goes on doing it through

outrageous storms, and years of service with little or no attention.

The only thing which has been a real problem is the regulator. These

tend to burn out. Brushes can also give problems but this is rare/unknown

on Scoraig.

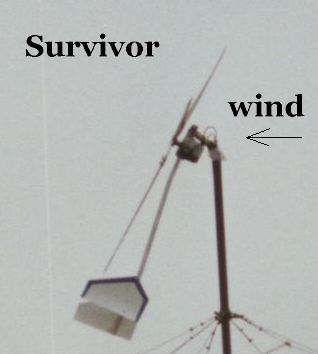

For 2 years I ran a Survivor S3000

wind turbine, which I had bought ex-demonstration. It was rather

out of date, and is now badged 'Synergy' instead. I believe they

have also put sliprings on it. I never had problems with cable twist,

but I did have problems with rain running into the yaw bearings, so that

they fell apart and the machine flew off the tower top. I also had

a blade root failure (see picture) where the mounting plate cracked across.

It ran for a few hours with 2 blades. This type of cracking has happened

to me before, with a Whisper 1000 'spring plate'. Seems like a highly stressed

piece of plate.

The furling system is fascinating, based on a hinge at the topmost point,

from which the windmill hangs. High winds blow it upwards until the

tail and blades are horizontal.

Another 'downwind' machine, which has fared much better here is the Proven.

Here is the 2.5kW machine at Scoraig. I did some development

work with it around 1995, leading to the use of double springs in the governing

system. This windmill does not furl by turning away from the wind

as most others do. It governs its blade speed accurately using centrifugal

force to alter the pitch of the blades.

The system puts quite a high stress onto the blades and springs, which

have sometimes cracked, and failed. For example the blades on the

Castaway machine at Taransay have just failed after very nearly two years

of high wind duty. One blade disappeared entirely.

Cracks in the polypropylene blades occur at the hinge points.

Cracks in the polypropylene blades occur at the hinge points.

Proven have recently introduced Polyurethane

hinges for their blade roots and these are proving to be much more

robust.

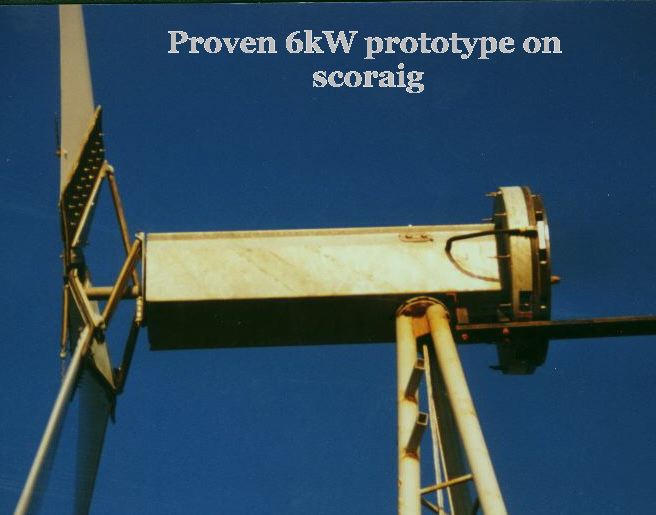

Scoraig is also the home of the prototype Proven 6kW machine which

is owned by my cousin Topher Dawson (boatbuilder and wind turbine blade

fabricator).

No more machines were built in this 'monocoque' style. The beam

on the right is for a balance weight, which is also unique to this prototype.

This windmill has worked well for about 3 years, with some nursing from

its owner. Unfortunately, the production versions still have some

problems to be worked through, but as usual, Proven

Engineering are working on solutions!

In this picture you can see the magnet rotor inside the alternator.

The cover was removed to improve cooling, and it looks nice too, wheeling

along.

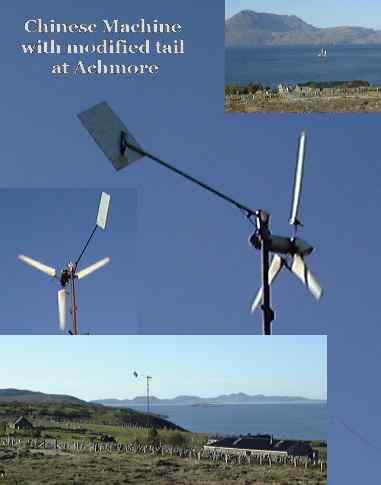

Here's a picture of a chinese wind turbine

which I have been testing. As supplied there were problems with its

balance and its furling system. After some early problems in 1998,

it has settled down to be quite a nice reliable machine .

PS we did have a blade fly off during the winter 2000-2001 and I have

now put the blades from the survivor on it.

this is typical of the sort of 'swift and grotty' repairs which keep scoraig

windmills going on a shoe-string long after they would have been abandoned

on other sites.

We also have some machines of my

own design here, for example the brakedrum windmill

(as written up in the Plans available from Picoturbine.com)

and the African 36

(see

this link too)

(see

this link too)

This wind turbine powers our home.

and now another one power Scoraig Secondary School

And one for william at Rhireavach..

another is located at Badrallach on the tarmac road, 10 miles from Dundonnell:-

Here is another one on Scoraig, installed sumer of 2000 for Bill Burstall

In this one you can see 3 AWP machines out of the 7 which are now up

and running in this area.

We have had some early problems related to manufacturing quality of

the alternator shaft, and cracks in the fibreglass blades, but there are

no real technical challenges remaining for this machine. It works.

It just remains to get on and install them.

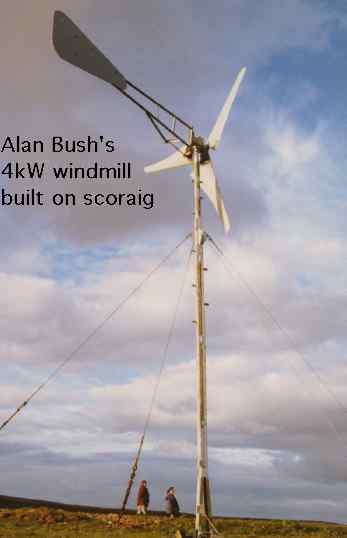

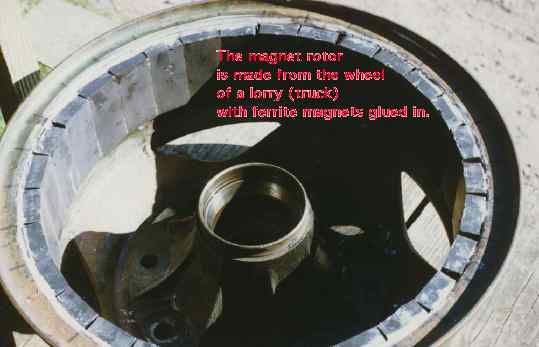

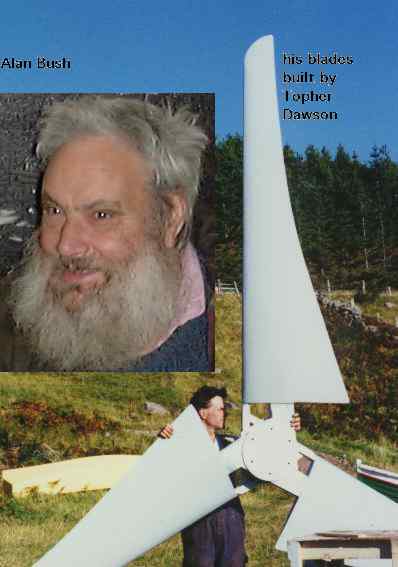

Another one to shout about is the 4kW heating machine I built with

help from Alan Bush and African Windpower in Zimbabwe (who made the stator

for me). African Windpower are working on a production version.

The blades were made

on Scoraig by Topher

Dawson.

The blades were made

on Scoraig by Topher

Dawson.

In the next picture you can see it being lowered for repair in June

2000.

It does have occasional problems, with rotor balance, stator insulation,

and suchlike, but it has run pretty consistently for nearly three years.

Here are a couple of pictures of locally produced

prototypes using the alternator I have designed for ITDG for local

manufacture in sri lanka

and peru. see also this link

for details of the alternator and how to build one.

Back to Hugh's

homepage